It was developed by the california based helisys inc.

Advantages of laminated object manufacturing.

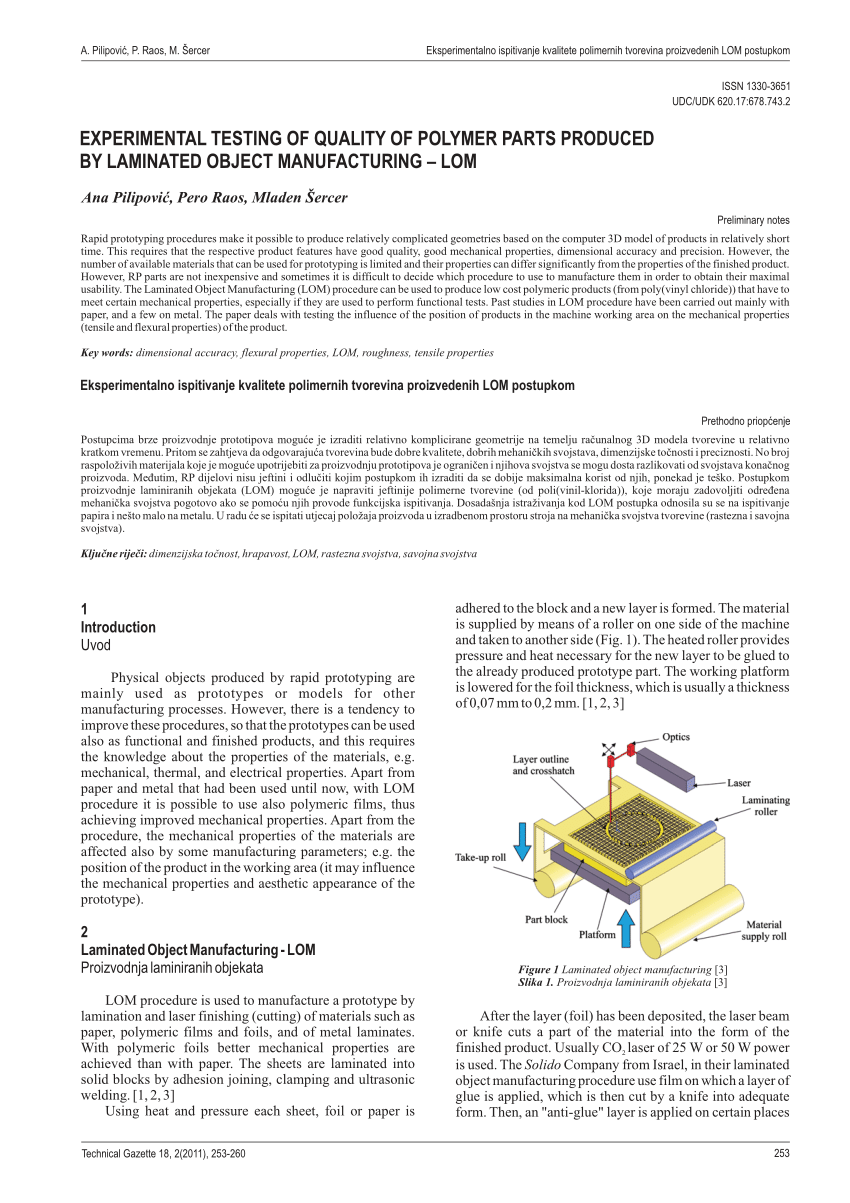

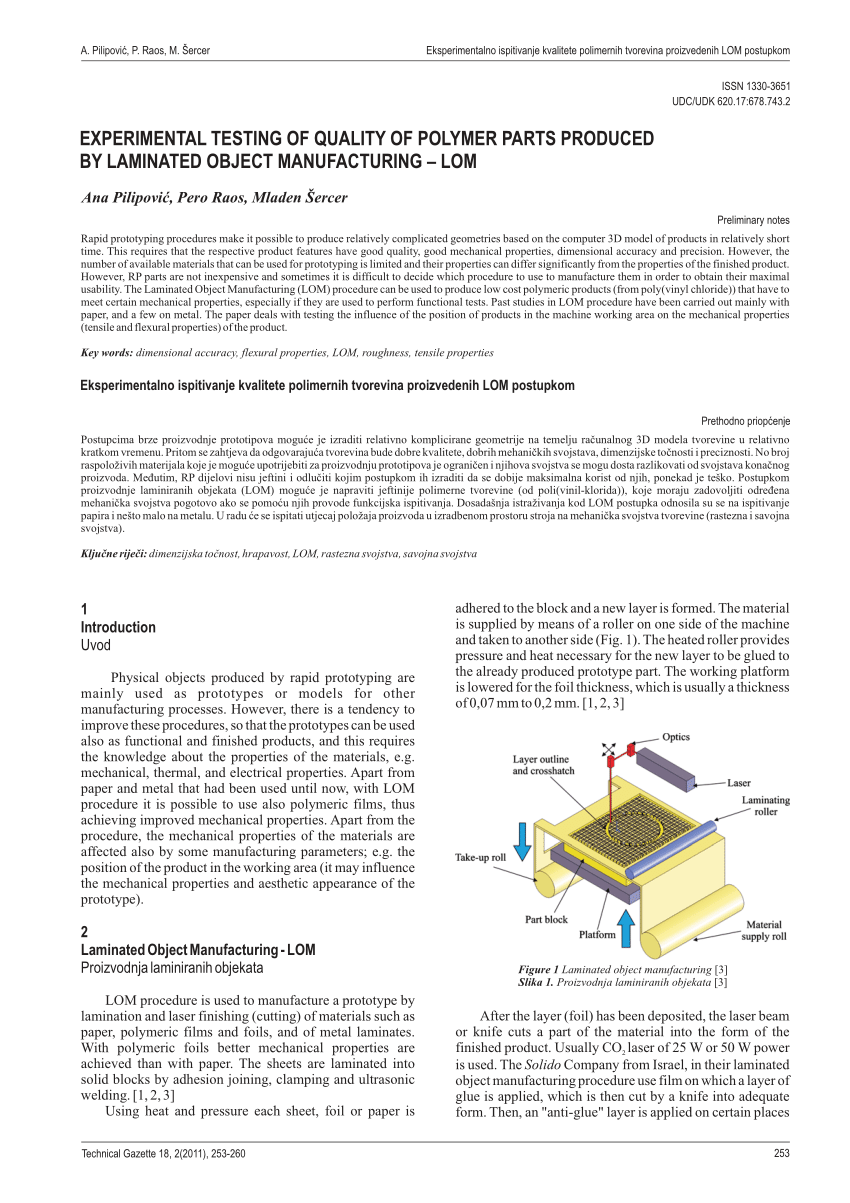

Lom august 12 2013 by michael jermann 1 comment laminated object manufacturing is a lesser known additive manufacturing process where an object is created by successively layering sheets of build material bonding them through heat and pressure and then cutting them into the desired shape using either a blade or a carbon laser.

Laminated object manufacture lom the laminated object manufacture lom process involves using a co 2 laser fitted on a 2d plotter to cut the components from thin layers of material.

Advantages ability to produce larger scaled models uses very inexpensive paper fast and accurate good handling strength environmentally friendly not health threatening.

Easy to build large models.

In comparison with alternative methods.

Disadvantages need for decubing which requires a lot of labor.

Parts are produced by stacking bonding and cutting layers of sheet material on top of the previous one.

4 2 2 2 laminated object manufacturing.

Laminated object manufacturing lom.

Laminated object manufacturing lom is a method of 3d printing.

The method studied in this paper is laminated object manufacturing lom.

Cubic technologies is now the successor organization of helisys in it layers of adhesive coated paper plastic or metal laminates are successively glued together and cut to shape with a knife or laser cutter objects printed with this technique may be additionally modified by machining or drilling.

Laminated object manufacturing is far less common than other commercialized additive manufacturing techniques though it is beginning to gain popularity within the maker movement.

The first lom fabrication system was developed in 1991 by helisys company.

Advantages and disadvantages.

Processing only possible at the perimeter.

In conclusion there are quite a few different ways to 3d print a part with unique advantages and disadvantages to each method.

Requires no support structures.

Lom is a kind of rapid prototyping technology which used raw materials in sheet forms.

Tassilo moritz saeed maleksaeedi in additive manufacturing 2018.

Availability of huge range leads to least wastage.

It is highly resistant to scratch and abrasion.

No chemical reaction so no chamber required.

Generally the system uses sheets of paper that are automatically placed on top of one another and adhered together using an adhesive.

Laminated object manufacturing lom is a rapid prototyping system developed by helisys inc.

Sweeping or vacuuming is typical all it takes to get laminate clean.