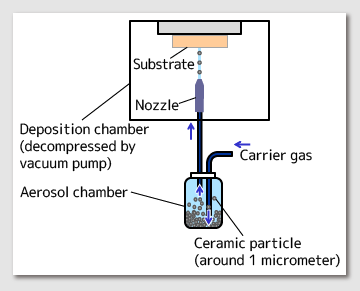

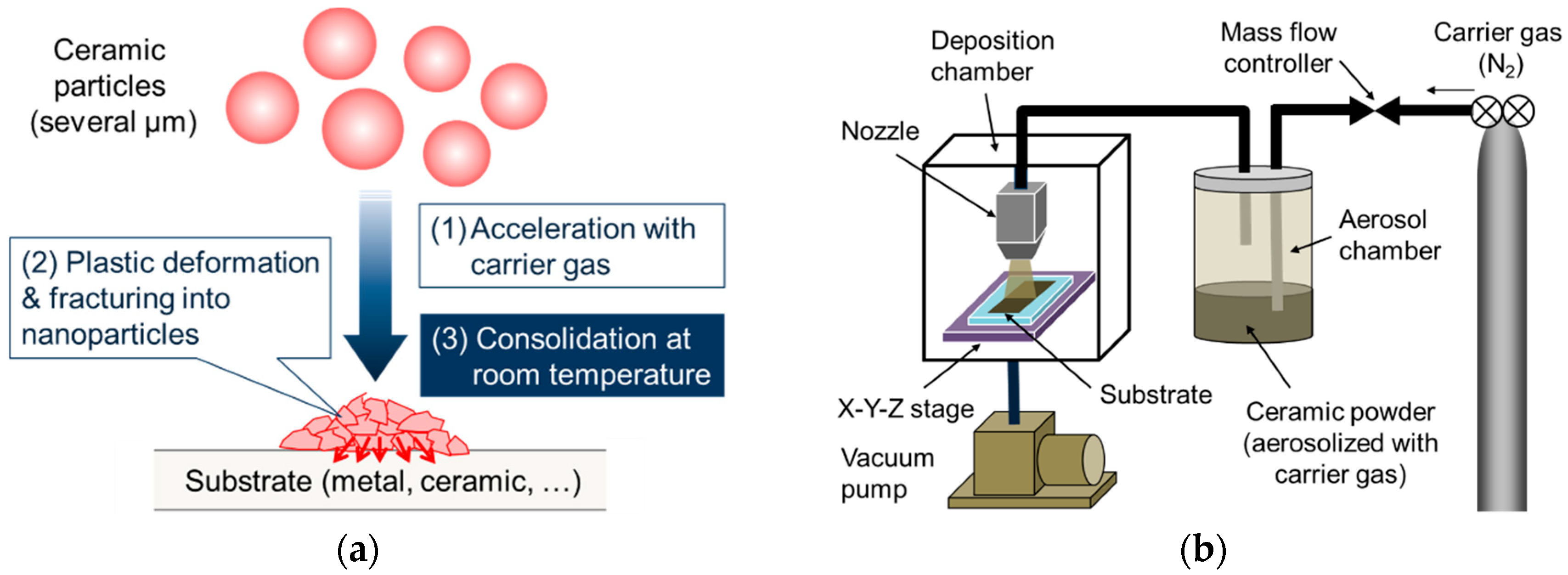

The aerosol deposition ad is a fi lm fabrication method1 2 that utilizes an impact solidifi cation phenomenon of ultra fi ne particles that was invented in 1997 by dr.

Aerosol deposition ceramic.

It is therefore highly attractive for industrial applications.

After the successful film formation mechanical film properties like hardness or plasma resistance are remarkably good.

However a novel spraying method powder aerosol deposition pad enables their production at normal room temperatures.

As an alternative the aerosol deposition ad method is a spray coating process to produce dense and nanocrystalline ceramic films at room temperature directly from an initial bulk powder on.

For a long time the production of ceramic coatings has only been possible by means of sintering techniques conducted at more than 1 000 degrees celsius.

Aerosol deposition ad is a newly developed ceramic film preparation technique in which the film is grown by injecting high speed 150 500 m s ceramic particles onto a substrate.

However a novel spraying method powder.

Jun akedo of the national institute of advanced industrial science and tech nology aist.

The presence of a vacuum and smaller starting particle size are among the most critical.

Ceramic film by aerosol deposition process ad film toto developed a unique y 2 o 3 film application by aerosol deposition ad process that provides outstanding plasma resistance for applications in semiconductor production equipment.

Powder aerosol deposition pad is a unique ceramic spray coating method that produces dense and well adhering thick films directly at room temperature without requiring any heating or sintering.

As an alternative the aerosol deposition ad method is a spray coating process to produce dense and nanocrystalline ceramic films at room temperature directly from an initial bulk powder on almost any substrate.

However actual deposition mechanism has not been clarified yet.

For a long time the production of ceramic coatings has only been possible by means of sintering techniques conducted at more than 1 000 degrees celsius.